As a high-precision and high-efficiency cutting equipment in modern industry, laser tube cutting machine is widely used in metal processing, automobile manufacturing, architectural decoration and other fields. However, the maintenance of its performance and life is highly dependent on the standardization of daily operation and maintenance. This article will summarize the tips for daily use of laser tube cutting machine from four dimensions: operation skills, maintenance safety matters and common problem solving, to help users improve efficiency, reduce costs and extend equipment life.

1. Pre-operation inspection and preparation: ensure stable operation of equipment

1. Comprehensive inspection of equipment status

Lubrication and tightening: Before starting the machine, check whether each lubrication point is short of oil (such as guide rails, lead screws, etc.), and manually apply special grease (such as molybdenum sulfide lithium grease). At the same time, confirm that the moving parts are not loose to avoid affecting the cutting accuracy due to mechanical vibration.

Safety device confirmation: Check whether the emergency stop button, protective cover, grating and other safety devices are normal to ensure that the machine can be stopped quickly in an emergency.

2. Calibration and debugging

Optical path correction: Before cutting every day, check whether the laser is emitted from the center of the nozzle. If it is offset, readjust the light to avoid deviation in the cutting path.

Air pressure and water temperature setting: After starting the oil pump, the system pressure should be kept within the specified range (usually 0.6-0.8MPa) to avoid excessive pressure to damage components or too low pressure to affect the cutting effect. The cooling water temperature is recommended to be controlled at 22-28℃, and can be appropriately increased to 28-32℃ in summer.

2. Cutting parameter optimization tips: improve accuracy and efficiency

1. Reasonably adjust the laser power

Adjust according to material characteristics: When cutting thin plates, increase the power appropriately (50-60% light intensity), and reduce the power for thick plates to avoid overheating. Long-term full-load operation (90-100% light intensity) will accelerate the aging of the laser tube. It is recommended to use medium and low power modes for daily use.

2. Optimize cutting path and parameters

Servo motor parameter matching: If elliptical or irregular phenomena occur when cutting circular holes, check whether the XY axis motion parameters of the servo motor match, and adjust the acceleration and speed curves to improve accuracy.

Blowing air pressure control: Too low blowing pressure can easily lead to edge carbonization, and too high blowing pressure may cause hole explosion. It is recommended to determine the optimal air pressure (usually 0.3-0.5MPa) through process tests and calibrate the air path system regularly.

3. Aperture and plate thickness ratio control

Follow the 1:1 aperture ratio principle: that is, the aperture should not be less than the material thickness. If the energy is insufficient when cutting small holes, breakpoints are likely to remain, which can be improved by reducing the speed or increasing the auxiliary gas pressure.

III. Daily maintenance and maintenance points: Extending equipment life

1. Cutting head and optical system maintenance

Lens cleaning: Check the protective lens (focusing lens, reflector) daily, use isopropyl alcohol or dust-free cloth to clean surface stains to avoid water stains. If the lens changes color or peels off, it needs to be replaced immediately.

Nozzle inspection: Select the appropriate nozzle type (conventional nozzles are used for flat pipes, and pointed nozzles are used for complex structures), and regularly check the roundness and cleanliness to prevent blockage from affecting the airflow.

2. Maintenance of mechanical transmission parts

Guide rails and lead screw lubrication: Clean the Z-axis guide rails and lead screws with a clean cloth every month, and apply lithium-based grease manually to ensure smooth movement.

Rack and chuck cleaning: Remove iron filings and foreign matter around the chuck every day, and regularly add molybdenum disulfide lithium-based grease to the gear parts to prevent wear.

3. Cooling and heat dissipation system management

Chiller maintenance: Replace distilled water and clean the water tank every month to prevent scale from clogging the pipeline. Clean the filter regularly to ensure the normal operation of the cooling fan.

Anti-condensation measures: In summer, configure an independent air-conditioned room for the laser to maintain a constant ambient temperature (25-30℃) to avoid condensation and damage to optical components due to temperature difference.

IV. Precautions for safe use: Ensure the safety of personnel and equipment

1. Operation specifications

Protective equipment is essential: Operators must wear protective glasses and gloves to avoid laser radiation and metal splashing.

Prohibition of illegal operation: It is strictly forbidden to put hands or foreign objects into the working area when the equipment is running. Press the emergency stop button immediately in case of emergency.

2. Environmental requirements

Temperature and humidity control: The working environment temperature is recommended to be 18-30℃, and the humidity is less than 70% to avoid high temperature and high humidity causing oxidation of electrical components.

Dust management: Install a dust collection device and clean the fan duct regularly to prevent smoke and dust from contaminating the lens and electronic components.

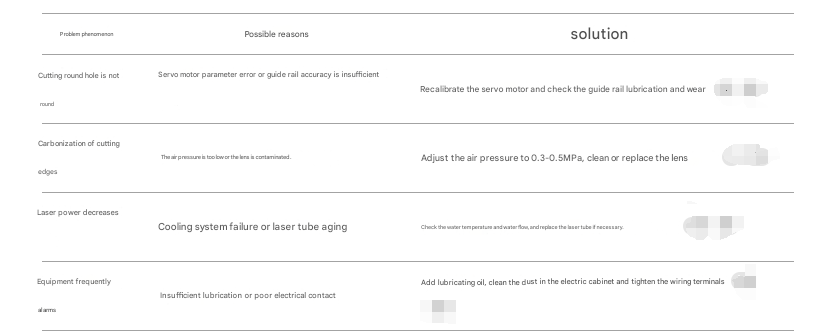

V. Quick solution guide for common problems

Conclusion

The efficient operation of the laser tube cutting machine is inseparable from standardized operation and meticulous maintenance. Through the above tips, users can not only improve the cutting quality and efficiency, but also significantly extend the service life of the equipment. It is recommended that enterprises establish a regular maintenance plan, train professional operators, and incorporate daily maintenance into standardized processes. For further information on equipment commissioning or troubleshooting, please refer to the technical manual provided by the manufacturer or contact the professional service team.

https://www.facebook.com/profile.php?id=61556689385404

https://www.youtube.com/channel/UCyvQ6yxtnvpK1umWcdE9YOQ